fast prototyping vs. manual prototyping: which one is more efficient?

Wiki Article

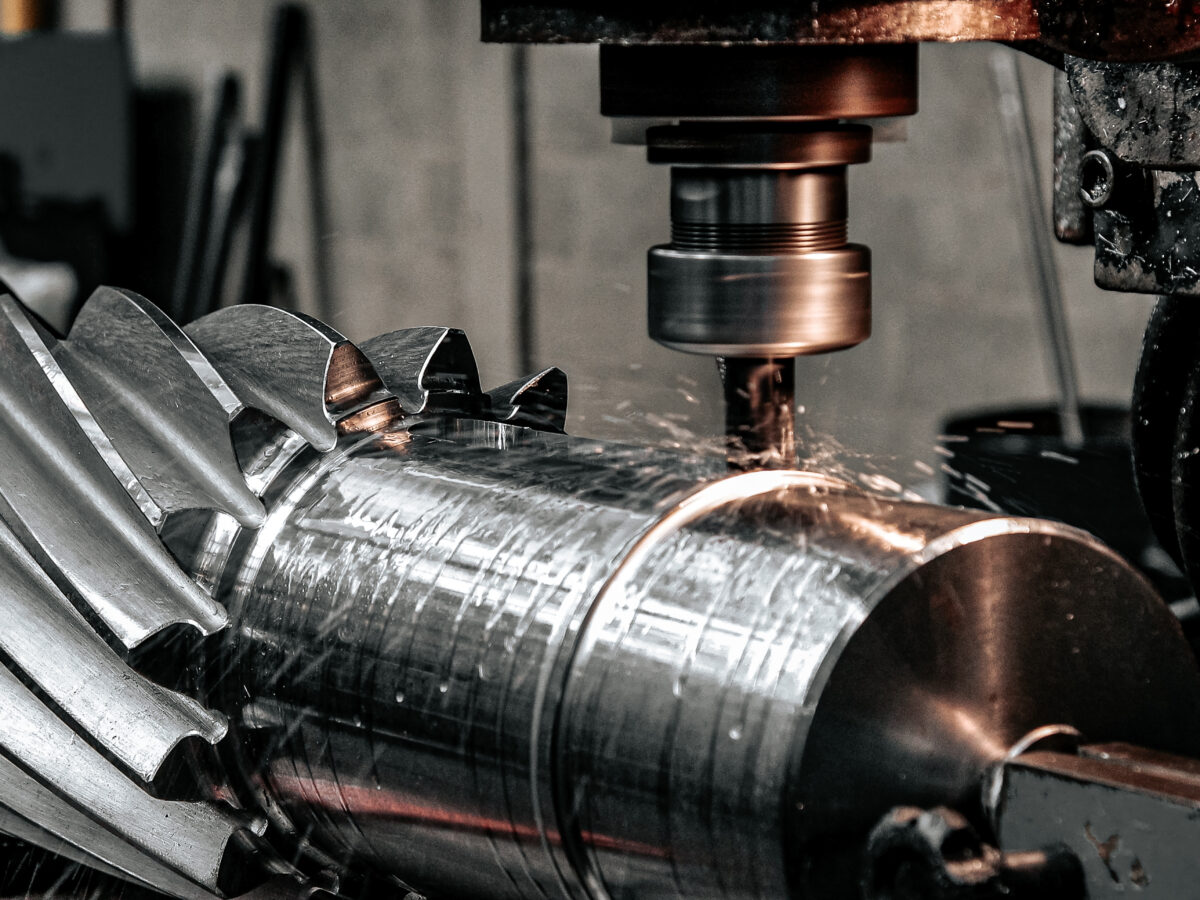

Boost Your Production Top Quality With Specialist CNC Machining Providers in Milling and Turning

CNC machining solutions in milling and transforming deal significant benefits for producing procedures. These procedures guarantee accuracy and effectiveness, important for producing top notch components. With advanced innovation and competent machinists, services can accomplish remarkable finishes and complex styles. Comprehending the subtleties of these services is important for optimizing their advantages. What factors should firms take into consideration when picking the ideal CNC machining companion?Understanding CNC Machining and Its Advantages

Numerous making processes exist, CNC machining stands out due to its precision and performance. This innovative production method utilizes computer-controlled devices to produce complex get rid of minimal human treatment. By automating the machining procedure, it greatly decreases the likelihood of human mistake, guaranteeing regular quality throughout manufacturing runsCNC machining supplies numerous benefits that appeal to different markets. To begin with, it fits complex designs that typical approaches might struggle to attain. In addition, the rate of production is enhanced, enabling for quicker turnaround times and enhanced result. In addition, CNC machining is functional, suitable for a vast array of products, consisting of plastics, compounds, and metals.

In addition, the procedure allows for very easy adjustments, allowing rapid prototyping and customization without comprehensive retooling. Consequently, organizations can respond quickly to market needs, making CNC machining a necessary component of modern-day production approaches.

The Value of Accuracy in Milling Processes

Precision is vital in milling procedures, as it directly affects the accuracy of the end product. The option of products also plays a significant duty, affecting how well the machining procedure fulfills defined tolerance criteria. Recognizing these aspects is vital for achieving excellent results in CNC machining.Role of Accuracy

Attaining high levels of precision is important in grating processes, as also the smallest discrepancy can bring about substantial mistakes in the last item. Accuracy in CNC machining straight influences the performance, performance, and long life of the made components. Accurate milling warranties that resistances and measurements are met, which is necessary for components that have to mesh effortlessly in setting up or run under certain conditions. Furthermore, the duty of accuracy extends to minimizing waste and rework, thus improving general production effectiveness. Advanced CNC equipments furnished with advanced software program and tooling contribute to achieving the required precision. By focusing on accuracy in milling, manufacturers can ensure top notch outputs that meet strict industry requirements and customer assumptions.

Product Option Impact

Material selection plays a crucial role in the milling procedure, affecting both the top quality of the last item and the efficiency of manufacturing. Different materials exhibit distinct properties such as hardness, tensile strength, and machinability, which straight affect the milling strategy used. For example, harder materials might require specific tools and slower feed prices to stop tool wear and maintain accuracy. Alternatively, softer products can be milled at higher speeds however may lack sturdiness. Additionally, the option of product can impact surface area finish and dimensional precision, requiring careful consideration by suppliers. Inevitably, selecting the appropriate product not only enhances item efficiency yet likewise optimizes the milling process, lowering waste and boosting overall performance.Tolerance Requirements Significance

While the selection of materials is vital, adherence to resistance requirements is equally critical in CNC machining procedures. Resistance requirements determine the acceptable limitations of variation in measurements, making certain components fit and function properly. In milling and transforming operations, exact resistances enhance product high quality, lower waste, and lessen rework. When resistances are properly preserved, manufacturers can accomplish constant outcomes, which is critical for industries such as aerospace, automobile, and clinical gadgets, where precision is extremely important. Discrepancies from developed criteria can result in assembly issues, jeopardized efficiency, and increased prices. Understanding and carrying out proper tolerance requirements is basic for any CNC machining service looking for to preserve high production high quality and meet customer specifications effectively.Enhancing Effectiveness Through Advanced CNC Turning

Advanced CNC transforming strategies significantly improve efficiency in component production by guaranteeing high precision in manufacturing. This raised precision not only enhances the total quality of the components produced yet additionally adds to lowered manufacturing time. Consequently, suppliers can accomplish greater output while keeping rigid high quality standards.Precision in Part Development

CNC turning modern technology has revolutionized precision in part production, making it possible for suppliers to attain extraordinary precision and efficiency. Utilizing computer-controlled lathes, this sophisticated process carefully forms products into complex layouts, ensuring limited resistances that satisfy requiring specs. The automation integral in CNC turning decreases human mistake, causing regularly high-quality elements customized to details requirements. Furthermore, the capacity to quickly change electronic designs permits for rapid iterations, enhancing the customization of components without compromising precision. Because of this, industries varying from aerospace to auto benefit substantially from these improvements, as they can generate complicated geometries easily. Eventually, CNC turning stands as a keystone of modern-day manufacturing, driving accuracy and reliability in element creation.Reduced Production Time

Key Technologies in CNC Machining

Various crucial technologies drive the performance and accuracy of CNC machining, allowing makers to generate intricate parts with high accuracy. Central to these developments are Computer system Assisted Layout (CAD) and Computer Helped Manufacturing (WEBCAM) software application, which improve the design-to-production process. CAD permits detailed designs to be produced and manipulated electronically, while camera converts these designs into machine guidelines.Better improving precision are multi-axis machining facilities, which allow cutting tools to move along multiple axes all at once, lowering the demand for several configurations - cnc turning service. In addition, advancements in tooling products try this website and coatings have actually boosted longevity and efficiency, permitting far better surface area finishes and extended tool life

Automation modern technologies, including robotics and smart software, promote real-time monitoring and modifications during production, ensuring uniformity and quality. Jointly, these technologies not only enhance production capacities yet also contribute to the total reliability of CNC machining solutions.

The Function of Knowledgeable Machinists in High Quality Manufacturing

Competent machinists play a vital role in ensuring the quality and precision of CNC machining manufacturing. Their know-how directly affects the result of manufacturing procedures, as they interpret technical illustrations, set up equipments, and choose appropriate tools for every task. By having a deep understanding of machining principles, they can make real-time modifications to optimize performance and keep limited resistances.Moreover, knowledgeable machinists employ their problem-solving abilities to determine and correct issues during manufacturing, protecting against flaws and ensuring that the end products meet strict high quality requirements. Their experience with various materials and machining methods allows them to adjust to varied job requirements, enhancing total efficiency

Additionally, these specialists frequently collaborate with designers and designers, providing beneficial understandings that add to the constant improvement of production techniques. Inevitably, the value of experienced machinists in CNC machining can not be overemphasized, as they develop the backbone of top notch manufacturing operations.

Decreasing Waste and Optimizing Resources

Effective CNC machining not just relies on the proficiency of skilled machinists yet also stresses the value of lowering waste and optimizing resources throughout the manufacturing procedure. By using advanced innovations and precise programming, makers can decrease product waste, making sure that every piece of basic material is used efficiently.Incorporating approaches such as nesting, where components are prepared to make the most of product usage, can especially lower scrap manufacturing. Furthermore, real-time tracking of device efficiency permits for instant adjustments, stopping overproduction and resource depletion.

Carrying out sustainable methods, such as reusing steel shavings and using environment-friendly materials, adds to both cost savings and environmental obligation.

With these actions, best site CNC machining solutions can enhance efficiency while maintaining premium requirements, ultimately leading to a much more lucrative and lasting procedure. By prioritizing source optimization, organizations can achieve greater effectiveness and a reduced ecological footprint in their production processes.

Picking the Right CNC Machining Service for Your Demands

How does one determine the most effective CNC machining service for certain job requirements? Selecting the proper CNC machining solution involves numerous vital factors to consider. Task specs, consisting of material dimensions, kinds, and resistances, have to be clearly defined. This assures that the picked solution can meet the technological demands of the project.Second, assessing the solution supplier's know-how and experience in the pertinent industry can give understandings into their abilities. Checking out past projects and customer endorsements can additionally inform the choice.

Third, assessing the readily available technology and machinery is necessary, as innovative devices usually brings about greater accuracy and effectiveness.

Expense and turnaround time must be considered to guarantee the service lines up with financial constraints and due dates. By thoroughly assessing these variables, businesses can recognize the CNC machining service that best fits their distinct manufacturing requirements.

Frequently Asked Inquiries

What Products Can Be Used in CNC Machining?

CNC machining can use a range of products including steels like steel, titanium, and aluminum, in addition to plastics such as acrylic and nylon, and compounds, giving flexibility for different manufacturing applications and markets.How much time Does a Common CNC Machining Job Take?

A common CNC machining project can take anywhere from a couple of days to numerous weeks, relying on elements such as intricacy, product kind, style specifications, and production quantity. Timelines vary based upon job requirements and urgency.Are CNC Machining Solutions Eco-friendly?

CNC machining solutions can be eco pleasant, particularly when using lasting products and effective procedures. Waste reduction and energy-efficient equipment contribute to a lower environmental impact, making these services a feasible choice for eco-conscious manufacturing.What Industries Generally Make Use Of CNC Machining Services?

CNC machining services are generally made use of in various industries, consisting of automobile, aerospace, electronic devices, clinical devices, and manufacturing. These sectors depend on precision machining for components that need high precision, performance, and repeatability in production procedures.Just How Can I Prepare My Layouts for CNC Machining?

To prepare layouts for CNC machining, one must guarantee appropriate documents layouts, enhance dimensions for tolerance, incorporate needed machining functions, and take into consideration product residential or commercial properties. In addition, offering detailed documentation can boost the manufacturing process's effectiveness and accuracy.While the choice of materials is crucial, adherence to resistance standards is equally important in CNC machining processes. Competent machinists play an important role in ensuring the quality and precision of CNC machining manufacturing. A regular CNC machining task can take anywhere from a few days to numerous weeks, depending on elements such as complexity, product type, style specifications, and manufacturing volume. CNC machining services can browse around this site be eco pleasant, specifically when utilizing sustainable materials and efficient procedures. To prepare styles for CNC machining, one ought to assure correct file layouts, maximize measurements for tolerance, integrate essential machining functions, and consider product residential or commercial properties.

Report this wiki page